Abstract

Paper

References

Projects Page

|

|

Paper

Superfluid helium

has unusual thermal and mechanical properties[1] and is well known for

it ability to spread over surfaces and to flow without dissipation through

even microscopic holes. Virtually all of the walls and surfaces used in

previous dissipationless flow experiments are wet by superfluid helium.

This effect means that droplets on these substrates are unstable and immediately

spread to form a smooth continuous film over the entire surface so that

vapor and substrate are never in contact. Recent work [2] has shown that

alkali metals are a special class of materials not completely wetted by

superfluid helium. In particular, cesium substrates can be used to prepare

superfluid samples with a distinctly different topology consisting of a

droplet with an edge where substrate, superfluid, and vapor meet at a three-phase

contact line [3]. We present here direct observations of isolated droplets

of superfluid on a substrate [4]. Both the static and dynamic behavior

of the droplets are unusual. We found that the contact angle was an extremely

hysteretic function of the volume of the drop. Perhaps the most remarkable

property of superfluid droplets is that they would not move across the

surface until a considerable force was applied to them. This result is

surprising because solid surfaces are well known not to exert transverse

forces on bulk superfluid or superfluid films without edges. Superfluid helium

has unusual thermal and mechanical properties[1] and is well known for

it ability to spread over surfaces and to flow without dissipation through

even microscopic holes. Virtually all of the walls and surfaces used in

previous dissipationless flow experiments are wet by superfluid helium.

This effect means that droplets on these substrates are unstable and immediately

spread to form a smooth continuous film over the entire surface so that

vapor and substrate are never in contact. Recent work [2] has shown that

alkali metals are a special class of materials not completely wetted by

superfluid helium. In particular, cesium substrates can be used to prepare

superfluid samples with a distinctly different topology consisting of a

droplet with an edge where substrate, superfluid, and vapor meet at a three-phase

contact line [3]. We present here direct observations of isolated droplets

of superfluid on a substrate [4]. Both the static and dynamic behavior

of the droplets are unusual. We found that the contact angle was an extremely

hysteretic function of the volume of the drop. Perhaps the most remarkable

property of superfluid droplets is that they would not move across the

surface until a considerable force was applied to them. This result is

surprising because solid surfaces are well known not to exert transverse

forces on bulk superfluid or superfluid films without edges.

Our apparatus consisted

of a substrate that can be rotated about a horizontal axis mounted in an

optical dewar with windows that provide an edge-on view of the substrate

as well as a view from above at an angle of 60° from the normal. The

substrate is a quartz microbalance with gold electrodes similar to those

used in our previous thermodynamic studies[5,6]. Fifty atomic layers of

cesium were vapor deposited onto the quartz and gold surfaces of the microbalance

at a rate of 0.01 layers/sec. During the evaporation, the temperature of

the substrate and the walls of the container were maintained below 6 K

to maintain ultra high vacuum conditions. The microbalance was used to

monitor the deposition and to perform thermodynamic characterizations of

the surface; the wetting temperature was measured to be Tw=2.04

K. A capillary tube (0.04 cm, outside diameter) attached to a source of

room-temperature gas through a mass flow controller provided a means of

putting drops of superfluid on the surface. The system was maintained at

liquid-vapor coexistence by filling the bottom of the container with bulk

liquid 4He. The drops were observed with a long focal distance

microscope that provided a magnification of approximately 30. Our apparatus consisted

of a substrate that can be rotated about a horizontal axis mounted in an

optical dewar with windows that provide an edge-on view of the substrate

as well as a view from above at an angle of 60° from the normal. The

substrate is a quartz microbalance with gold electrodes similar to those

used in our previous thermodynamic studies[5,6]. Fifty atomic layers of

cesium were vapor deposited onto the quartz and gold surfaces of the microbalance

at a rate of 0.01 layers/sec. During the evaporation, the temperature of

the substrate and the walls of the container were maintained below 6 K

to maintain ultra high vacuum conditions. The microbalance was used to

monitor the deposition and to perform thermodynamic characterizations of

the surface; the wetting temperature was measured to be Tw=2.04

K. A capillary tube (0.04 cm, outside diameter) attached to a source of

room-temperature gas through a mass flow controller provided a means of

putting drops of superfluid on the surface. The system was maintained at

liquid-vapor coexistence by filling the bottom of the container with bulk

liquid 4He. The drops were observed with a long focal distance

microscope that provided a magnification of approximately 30.

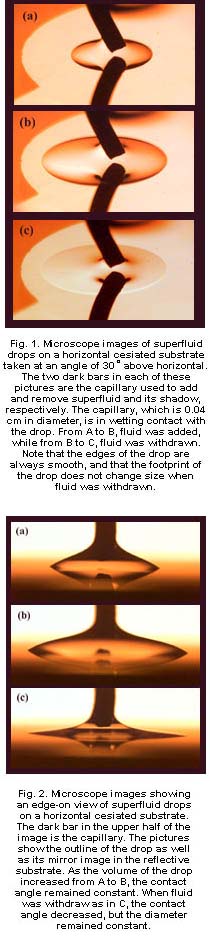

Figures 1 and 2 show

a sequence of photographs of superfluid drops on a cesiated substrate at

T=1.16K. Figure 1 shows pictures taken with the microscope looking down

on the substrate at an angle of 30° above the horizontal. The dark

bar at the top of the pictures is the capillary tube, and the lower bar

is its shadow. The tube was left in contact with the superfluid drop so

that fluid could be added and withdrawn. This geometry is conventional

for contact angle measurements and typically yields the advancing and receding

contact angle[7]. The drops appear oval because of the viewing angle. The

edge of the gold electrode can be seen in the extreme and upper left; the

cesium film is too thin to provide appreciable optical contrast. Figure

2 shows edge-on views of the same droplets as shown in Figure1 illuminated

from the back. The optical axis is a fraction of a degree above horizontal,

so that both the free surface of the drop and its reflection in the substrate

are visible. The capillary tube is clearly visible protruding from the

top of the drop. The focus was adjusted so that a diameter of the drop

lies in the focal plane. Figures 1 and 2 show

a sequence of photographs of superfluid drops on a cesiated substrate at

T=1.16K. Figure 1 shows pictures taken with the microscope looking down

on the substrate at an angle of 30° above the horizontal. The dark

bar at the top of the pictures is the capillary tube, and the lower bar

is its shadow. The tube was left in contact with the superfluid drop so

that fluid could be added and withdrawn. This geometry is conventional

for contact angle measurements and typically yields the advancing and receding

contact angle[7]. The drops appear oval because of the viewing angle. The

edge of the gold electrode can be seen in the extreme and upper left; the

cesium film is too thin to provide appreciable optical contrast. Figure

2 shows edge-on views of the same droplets as shown in Figure1 illuminated

from the back. The optical axis is a fraction of a degree above horizontal,

so that both the free surface of the drop and its reflection in the substrate

are visible. The capillary tube is clearly visible protruding from the

top of the drop. The focus was adjusted so that a diameter of the drop

lies in the focal plane.

The plane of the substrate

can be located by drawing a line between the two points where the profile

of the drop meets its mirror image. The contact angle is the angle between

the tangent to the drop profile and the substrate at the point of contact.

Despite the superfluidity of the drops, the value of the contact angle

which we observed depended critically on the way the drop was prepared.

When the volume of the drop was increasing, the contact angle was approximately

32° [8] and independent of the volume of the drop; Figure 2A and B,

show snapshots of the same drop as fluid was added (the corresponding top

view of the growing drop is shown in Figure 1A and B). When fluid was withdrawn,

the contact line remained stationary and the receding contact angle approached

zero, (Figures 1C and 2C). The bulk fluid could be completely removed,

but apparently a thin film remained in the region bounded by the original

contact line, since when fluid is added, the drop immediately obtained

its previous diameter and only slowly increased its volume and contact

angle. The only way to prepare a smaller drop (such as Figure 1A) in the

same area was to remove the microscopic film by briefly heating the substrate

with a flash of light. The plane of the substrate

can be located by drawing a line between the two points where the profile

of the drop meets its mirror image. The contact angle is the angle between

the tangent to the drop profile and the substrate at the point of contact.

Despite the superfluidity of the drops, the value of the contact angle

which we observed depended critically on the way the drop was prepared.

When the volume of the drop was increasing, the contact angle was approximately

32° [8] and independent of the volume of the drop; Figure 2A and B,

show snapshots of the same drop as fluid was added (the corresponding top

view of the growing drop is shown in Figure 1A and B). When fluid was withdrawn,

the contact line remained stationary and the receding contact angle approached

zero, (Figures 1C and 2C). The bulk fluid could be completely removed,

but apparently a thin film remained in the region bounded by the original

contact line, since when fluid is added, the drop immediately obtained

its previous diameter and only slowly increased its volume and contact

angle. The only way to prepare a smaller drop (such as Figure 1A) in the

same area was to remove the microscopic film by briefly heating the substrate

with a flash of light.

Contact angle hysteresis

is a common phenomenon in wetting measurements of conventional liquids

and substrates that is typically attributed to substrate heterogeneity,

or kinetic effects associated with the viscosity of the liquid, or both

[7,9,10]. Because our experiment utilized superfluid and the time scale

of the observations was several minutes, kinetics cannot be invoked to

explain the hysteresis we observed. Similarly, it is difficult to find

a plausible source of surface heterogeneity, because the substrate exhibits

the same sharp thermodynamic signatures of the wetting transition that

we have explored in previous work[5,6]. In order to explain a receding

contact angle of zero, standard models based on consideration of metastable

states on a heterogeneous substrate would require that more than half of

the surface be covered with patches where the local contact angle is zero,

that is, where the liquid wets[7,10]. This possibility is ruled out by

microbalance measurements which show that the average equilibrium coverage

at liquid-vapor coexistence on our substrate at temperatures far below

the wetting temperature is less than 2 monolayers, which implies that the

fraction of the surface that was wetted is less than 4%. The possibility

of point-like pinning centers also seems unlikely because the contact line

(Fig 1) appears perfectly smooth on length scales of a few micrometers. Contact angle hysteresis

is a common phenomenon in wetting measurements of conventional liquids

and substrates that is typically attributed to substrate heterogeneity,

or kinetic effects associated with the viscosity of the liquid, or both

[7,9,10]. Because our experiment utilized superfluid and the time scale

of the observations was several minutes, kinetics cannot be invoked to

explain the hysteresis we observed. Similarly, it is difficult to find

a plausible source of surface heterogeneity, because the substrate exhibits

the same sharp thermodynamic signatures of the wetting transition that

we have explored in previous work[5,6]. In order to explain a receding

contact angle of zero, standard models based on consideration of metastable

states on a heterogeneous substrate would require that more than half of

the surface be covered with patches where the local contact angle is zero,

that is, where the liquid wets[7,10]. This possibility is ruled out by

microbalance measurements which show that the average equilibrium coverage

at liquid-vapor coexistence on our substrate at temperatures far below

the wetting temperature is less than 2 monolayers, which implies that the

fraction of the surface that was wetted is less than 4%. The possibility

of point-like pinning centers also seems unlikely because the contact line

(Fig 1) appears perfectly smooth on length scales of a few micrometers.

Although the conventional

explanations of contact angle hysteresis due to surface heterogeneity do

not apply to our experiment, there must nevertheless be some mechanism

which provides metastable states that can trap the droplet in configurations

with a continuous range of contact angles. The fact that the contact line

did not move even when the apparent contact angle was reduced to zero when

the drop was deflated allows us to place a lower limit on the pinning force

per unit length which these metastable states can sustain. We assume as

is customary that the advancing contact angle is equal to the thermodynamic

equilibrium contact angle q [8] which satisfies

Young’s equation , slv cosq

= ssv- ssl

where the sij are surface tensions,

and the l,s,v subscripts denote liquid, substrate, and vapor, respectively.

In this case, the force per unit length on the contact line due to surface

tension when the contact angle was reduced to zero is slv

(1- cosq) = 46 mdyne/cm. The maximum pinning

force must be at least as large. Although the conventional

explanations of contact angle hysteresis due to surface heterogeneity do

not apply to our experiment, there must nevertheless be some mechanism

which provides metastable states that can trap the droplet in configurations

with a continuous range of contact angles. The fact that the contact line

did not move even when the apparent contact angle was reduced to zero when

the drop was deflated allows us to place a lower limit on the pinning force

per unit length which these metastable states can sustain. We assume as

is customary that the advancing contact angle is equal to the thermodynamic

equilibrium contact angle q [8] which satisfies

Young’s equation , slv cosq

= ssv- ssl

where the sij are surface tensions,

and the l,s,v subscripts denote liquid, substrate, and vapor, respectively.

In this case, the force per unit length on the contact line due to surface

tension when the contact angle was reduced to zero is slv

(1- cosq) = 46 mdyne/cm. The maximum pinning

force must be at least as large.

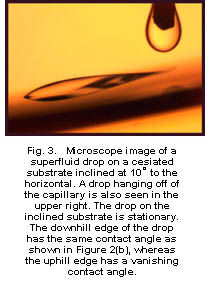

Another manifestation

of forces on the contact line can be seen when a superfluid drop was placed

on an inclined surface. Figure 3 shows an edge-on view of a drop on a cesiated

surface inclined at ~ 10° to the horizontal; a pendant drop of fluid

formed by forcing helium down the capillary faster than the superfluid

film on the outer surface could drain it, can also be seen in the upper

right corner. The most remarkable feature of the drop on the substrate

is that it is stationary. Even vigorous shaking of the apparatus, which

caused easily discernible waves in the drop, did not cause it to flow down

the incline. The downhill edge of the drop had the same contact angle as

the advancing edge of a growing drop, while the uphill edge had a vanishing

contact angle. As more fluid was added to the drop, it eventually rolled

down the incline, often with a jerky stick-slip motion. Subsequent drops

immediately spread out across the path of the previous drop and rapidly

flowed downhill. It seems as if the first drop, which moves across a dry

substrate left a trailing film that “lubricates” the motion of subsequent

drops. This film, which persisted for hours, may be related to the metastable

thick films we have observed in previous experiments[6]. The trailing film

had submicroscopic thickness and was invisible in an edge-on view. It could

be detected ellipsometrically and was superfluid because locally heating

a spot with a laser beam produced a thermo-mechanically driven bump in

the film profile. Another manifestation

of forces on the contact line can be seen when a superfluid drop was placed

on an inclined surface. Figure 3 shows an edge-on view of a drop on a cesiated

surface inclined at ~ 10° to the horizontal; a pendant drop of fluid

formed by forcing helium down the capillary faster than the superfluid

film on the outer surface could drain it, can also be seen in the upper

right corner. The most remarkable feature of the drop on the substrate

is that it is stationary. Even vigorous shaking of the apparatus, which

caused easily discernible waves in the drop, did not cause it to flow down

the incline. The downhill edge of the drop had the same contact angle as

the advancing edge of a growing drop, while the uphill edge had a vanishing

contact angle. As more fluid was added to the drop, it eventually rolled

down the incline, often with a jerky stick-slip motion. Subsequent drops

immediately spread out across the path of the previous drop and rapidly

flowed downhill. It seems as if the first drop, which moves across a dry

substrate left a trailing film that “lubricates” the motion of subsequent

drops. This film, which persisted for hours, may be related to the metastable

thick films we have observed in previous experiments[6]. The trailing film

had submicroscopic thickness and was invisible in an edge-on view. It could

be detected ellipsometrically and was superfluid because locally heating

a spot with a laser beam produced a thermo-mechanically driven bump in

the film profile.

Superfluid droplets on

cesiated substrates have remarkable spreading and flow properties that

are not simple consequences of bulk superfluid behavior. Liquid helium

has exceptional chemical purity and the heterogeneity of our cesium surface

is constrained by thermodynamic adsorption measurements. For these reasons,

helium on cesium would naively be expected to display nearly ideal reversible

spreading behavior, because even the complications due to viscosity are

negligible. In contrast, superfluid contact angles are found to be even

more hysteretic than typical classical fluid drops on macroscopically heterogeneous

surfaces. The hysteresis is so extreme that the superfluid contact line

appears to move in only one direction, that is so as to increase the wetted

area. Superfluid droplets on

cesiated substrates have remarkable spreading and flow properties that

are not simple consequences of bulk superfluid behavior. Liquid helium

has exceptional chemical purity and the heterogeneity of our cesium surface

is constrained by thermodynamic adsorption measurements. For these reasons,

helium on cesium would naively be expected to display nearly ideal reversible

spreading behavior, because even the complications due to viscosity are

negligible. In contrast, superfluid contact angles are found to be even

more hysteretic than typical classical fluid drops on macroscopically heterogeneous

surfaces. The hysteresis is so extreme that the superfluid contact line

appears to move in only one direction, that is so as to increase the wetted

area.

It is difficult to reconcile

these observations with standard models of contact angle hysteresis. Regarded

as a superfluid, droplets are remarkable because they can resist flow against

a substantial chemical potential gradient. Both of these effects are presumably

due to metastable configurations of the superfluid contact line, which

have been inaccessible to experimental observation until very recently.

In order to attribute the metastability to extrinsic defects, a mechanism

allowing small defect concentrations to cause extremely large hysteresis

would need to be identified. It is difficult to reconcile

these observations with standard models of contact angle hysteresis. Regarded

as a superfluid, droplets are remarkable because they can resist flow against

a substantial chemical potential gradient. Both of these effects are presumably

due to metastable configurations of the superfluid contact line, which

have been inaccessible to experimental observation until very recently.

In order to attribute the metastability to extrinsic defects, a mechanism

allowing small defect concentrations to cause extremely large hysteresis

would need to be identified.

This work supported by NSF grant DMR 9623976.

|

|